Professionals

We are Changing the Future of Prosthetics

And probably the future of your practice, too.

Founded in 2017, Xtremity has followed an intentional path to develop thermoformable socket technology and cost-efficient fabrication processes that will have a life-changing impact on prosthetic care for individuals with transtibial limb loss/difference, as well as the prosthetists who care for them.

Here's the gist:

Our materials are better for your health because you’re not breathing in toxic fumes, better for the environment because we’re majorly cutting down on waste, and better for your patients because they don’t have to spend their time in discomfort, going to and from appointments.

We cut down fabrication time significantly, allowing a quicker time to delivery of a definitive socket. You can deliver the prosthesis in days rather than weeks and then adjust the socket with a heat gun an unlimited number of times in your office… in minutes.

Your patients are thrilled. You’re thrilled. Everyone wins.

Instructional Downloads

Below are some PDF downloads to help you as you learn to use Xtremity’s products.

Heat

Place the XtremityTT® Preform into the Benchtop Heating Unit.

Shape

Once heated, the XtremityTT® Preform is thermoformable over a positive limb model under vacuum.

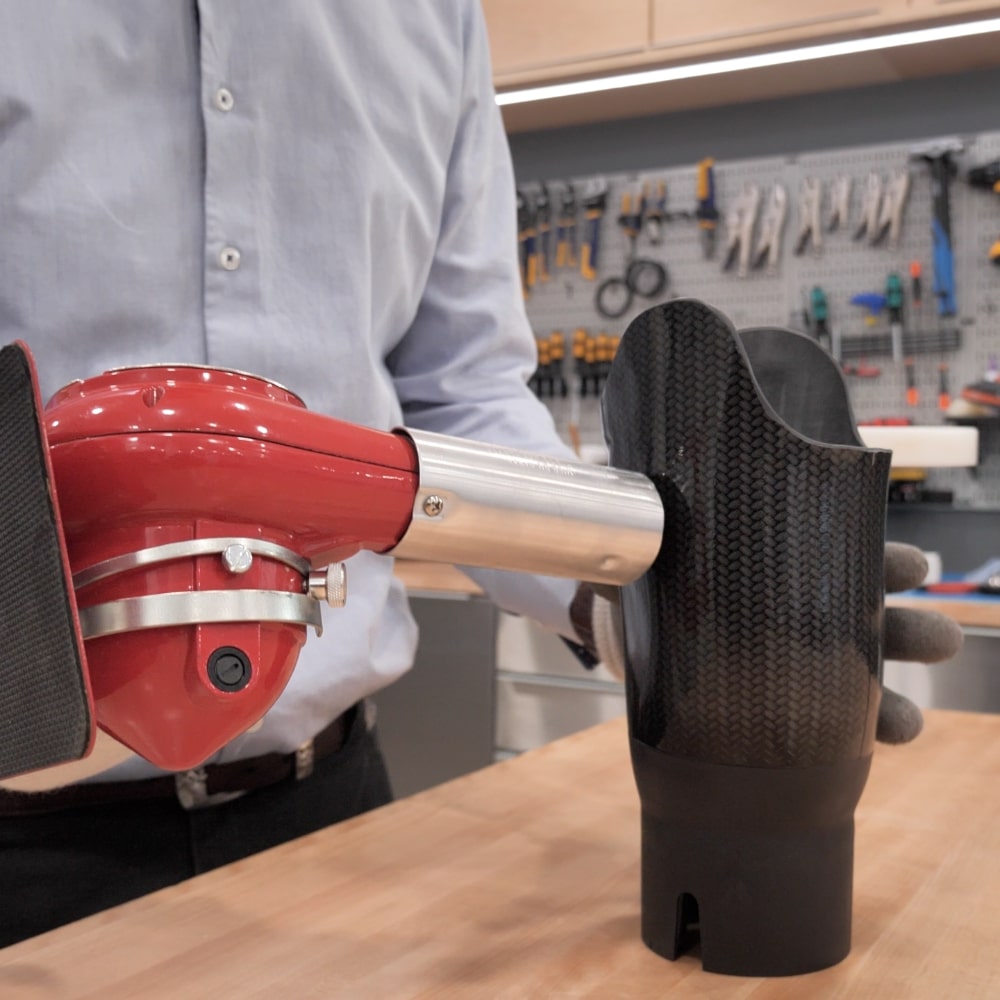

Assemble

Assemble distal componentry with modular and interchangeable suspension systems and alignment base that offers up to 16mm slide and 30 degrees of rotations adjustment.

Adjust

Spot-heat and adjust the socket using a heat gun an unlimited number of times throughout the life of the prosthesis.

What will you do with the time you save?

Will you see more patients? Get home earlier to your family? The possibilities are endless!

Xtremity Academy

Xtremity Academy offers multiple opportunities to become certified in the XtremityTT® Socket System and earn ABC Continuing Education Units as well.

Certification is required for the purchasing of Xtremity systems. Each course is eligible for ABC CEUs with a minimum passing score of 80% on the final quiz and will be reported at the end of each month. Educational materials were developed and designed by Xtremity’s knowledgeable team of clinicians.

Live Events

XtremityTT® Socket System Overview – 2 CEUs

Learn how to fabricate an XtremityTTTM Socket System during this in person course. We will cover the XtremityTT® Socket System product details, features, benefits, a fabrication demonstration, and hands-on practice.

XtremityTT® Socket System Comprehensive Training – 4 CEUs

Take an in-depth look at the science and technology that went into the development of the XtremityTTTM Socket System. This extensive in person course will cover the XtremityTT® research, development, testing, product details, features, benefits, a fabrication demonstration, and an extended hands-on practice session.

To schedule a live event, contact your local sales representative or call customer service at: 970-429-4203 ext. 102 or email hello@xtremity.com

Virtual Webinar Events

XtremityTT® Socket System Overview Webinar– 2.25 CEUs

Explore the XtremityTT® Socket System via live webinar with one of our highly trained clinicians. Webinars will be conducted on a semi-monthly basis and can be set up for individual clinic training needs as well. This event will include a virtual instructor to demonstrate XtremityTT® Socket fabrication and Q&A.

Upcoming Webinar Dates:

- October 25, 1:00 pm Mountain Time

Tutorial Videos

Check out the Xtremity YouTube channel for tutorials, patient testimonials, and more.

Instructional Downloads

Below are some PDF downloads to help you as you learn to use Xtremity’s products.

More Xtremity Benefits

Diabetes or Vascular Disease

Patients with diabetes or vascular disease who are more at risk when their leg changes size or shape – the prosthetist can make a quick adjustment before there is a serious problem

Veterans Administration

Patients who are treated by Veterans Administration medical centers and their contracted O&P providers who often travel from long distances and can benefit from a socket that is easy to fabricate and easy to adjust

Limited Lab Space

Clinics located in a hospital or physician office building that is expensive real estate with limited lab space

Ancillary and Rural Clinics

Prosthetists working in ancillary and rural clinics that rely on technicians and equipment in a distant centralized lab

Mobile O&P Providers

Mobile O&P providers who work out of a lab on wheels

Transportation Challenges

Patients traveling a long distance and patients experiencing transportation challenges

- Patients with diabetes or vascular disease who are more at risk when their leg changes size or shape – the prosthetist can make a quick adjustment before there is a serious problem

- Patients who are treated by Veterans Administration medical centers and their contracted O&P providers who often travel from long distances and can benefit from a socket that is easy to fabricate and easy to adjust

- Clinics located in a hospital or physician office building that is expensive real estate with limited lab space

- Prosthetists working in ancillary and rural clinics that rely on technicians and equipment in a distant centralized lab

- Mobile O&P providers who work out of a lab on wheels

- Patients traveling a long distance and patients experiencing transportation challenges

Embrace the evolution!

Frequently Asked Questions

We’re going to be fully transparent: the XtremityTTTM Socket System is not the cheapest option out there. Your up-front costs will be more than fabricating a carbon fiber laminated socket in-house. Allow us to explain why.

We set out to solve a problem: ongoing adjustability of prosthetic sockets that takes a fraction of the time to fabricate. We believe patients with transtibial limb loss/difference deserve access to socket technology that isn’t decades old and that offers meaningful improvements to adjustability, comfort, and convenience.

Not only does our system solve this problem, saving patients countless hours of discomfort and multiple fitting appointments — it also saves you, the clinician, precious time to run your clinic, grow your business, enjoy work-life balance, and more.

Now you are able to heat, thermoform, trim, assemble, and have the prosthesis ready to fit in less than an hour, and your patients can walk out comfortably in their newly fitted prosthesis.

What will you do with the time you save? See more patients? Get home early to your family? Start a new hobby? The possibilities are endless.

Contact us for a quote and to learn more about adding this life-changing technology to your clinic.

XtremityTTTM utilizes a unique socket “preform” that is injection molded using a proprietary carbon reinforced polymer. Our system is fabricated, eliminating variables and reducing hazardous exposures (chemicals, fumes, carbon dust) associated with the layup, lamination and grinding of a traditional carbon socket.

Our unique polymer blend provides the durability of a carbon fiber laminated socket, while achieving the benefits of adjustability and rapid fabrication.

The XtremityTTTM Socket System is the most tested definitive socket ever.

- Patient Tested & Approved: XtremityTTTM has over 30 million steps from all types of users, conditions/terrains, and activities.

- Meets & Exceeds Industry Standards: XtremityTTTM is setting the standard for socket testing. The socket has passed rigorous durability and thermal testing. All materials componentry have passed ISO 10328 standards.

- Clinical Trial Success: A 38-patient IRB approved clinical trial reported major benefits.

In short, yes — it’s durable.

- Shorter time to delivery — your prosthetist can fabricate your socket in as little as one hour!

- Less fitting and adjustment appointments = less time away from work and family

- More comfortable fit with softer edges and less rigid feel that is heat-adjustable to conform to your limb as it changes. Ongoing adjustments can be made by your prosthetist in just 10 minutes.

- In a 38-patient clinical trial, when the sockets were duplicated, 81% of patients preferred their XtremityTTTM Socket over their carbon fiber laminated socket.

All our products are designed, tested, and manufactured in the USA.

Clinical Team