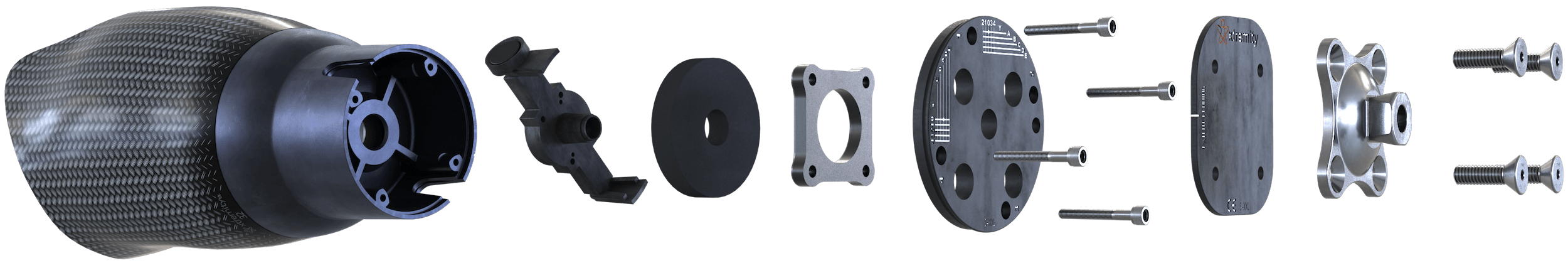

Modular Base Housing

Thermoformable Socket

Suspension Bridge

Bridge Foam Spacer

Bolt Ring

Base Plate

Base Plate Screws

Base Cover

4-Hole Adapter

Pyramid Screws

XtremityTT® Preform Socket

Each preform is injection molded with a distal base that is connected to the modular suspension system and alignment base. We offer 7 sizes in standard and conical profiles.

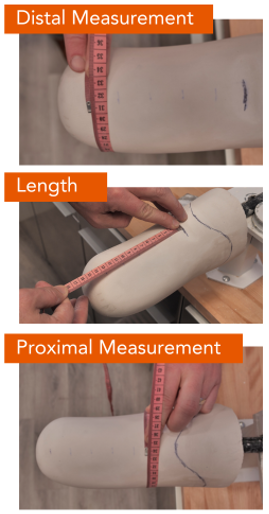

Sizing Calculator

Choosing the correct size XtremityTT Preform is important for optimal socket wall thickness and strength. XtremityTT Preforms are available in Standard and Conical Profiles. Sizing is determined using 3 measurements below to find your correct size. (all measurements are in cm)

XtremityTT® FLEX

A flexible inner socket that provides uniform wall thickness, is easy to fabricate with minimal lab space and equipment, and reduces material waste.

To support the patient’s continuous, comfortable, and long-term use of their prosthesis, the prosthetist can use a heat gun to make spot adjustments at any time throughout the life of the prosthesis.

Environmental / Health Benefits

Fabrication and assembly of the XtremityTTTM socket is accomplished in about one hour, in a small workspace, without a large oven or vented room for grinding and finishing the socket.

No layup. No lamination. No hazardous raw materials or irritating carbon dust. XtremityTTTM is a healthier choice for clinic employees and more sustainable for our environment.

Quality Manufacturing in the USA

The Most Tested Socket Ever

While there are no existing standards or requirements for socket testing, Xtremity’s product development and engineering team completed the most testing ever on transtibial socket technology. Xtremity invested millions of dollars creating precise methods and devices to conduct a vast range of tests to validate the structural durability, performance, safety and benefits of the XtremityTTTM Socket System.

The XtremityTTTM Socket System was load tested (3 million cycles, heel and toe) adhering to ISO standards for prosthetic devices. A 38-patient controlled study involving six clinics, as well as a battery of tests for ultimate strength, torsion, pressure mapping and material creep, were completed prior to the product’s release. Patient “testers” included extreme athletes who logged more than 30 million steps.